Maruti Suzuki India adapts to the requirements of the automotive future

Maruti Suzuki India plans to close its diesel engine factory in Gurgaon as the biggest setback for the diesel drive in India so far. They would like to convert the existing production line for petrol engines or create an additional one in the factory Manesar. Maruti’s decision highlights the dwindling demand for diesel vehicles in the Indian market. Instead, they want to focus more on gasoline or gas powered vehicles and green hybrid and electric vehicles. As India’s largest automaker, Maruti benefits from the cooperation of the parent company Suzuki and Toyota in the production of hybrid and electric vehicles.

The sales of diesel vehicles in India are expected to fall sharply in April 2020 when the more stringent BS VI emission standard comes into effect. The further development of existing diesel engines from the BS IV emissions standard to BS VI will make them considerably more expensive and thus less attractive. In the past four years, the market share of gasoline engines in India has increased from 47 to 60 percent, while the share of diesel vehicles has fallen from 53 to 40 percent. Maruti is currently assembling a 1.3-liter Fiat diesel engine at the Gurgaon plant, which is installed in the extremely successful Baleno, Vitara and Ertiga models. In addition, the small truck Maruti Super Carry uses a self-developed 800 cc diesel engine.

Meanwhile, Suzuki has already begun developing a full hybrid car for the Indian market. A record $ 1.4 billion was earmarked as R & D budget for 2019, most of it for hybrid and electric vehicles. The company also asked the Indian government to increase the number of LPG outlets as Maruti’s gas-powered vehicles grew 50 percent last year. According to Maruti Suzuki India CEO, Randhir Singh Kalsi, adapting to customer needs have allowed us to test new approaches and develop these innovative models.

Are you in the automotive industry and do you want to export your products to India? Before that, the products have to be certified according to the Automotive Industry Standard (AIS). We advise you in advance and accompany you competently throughout the India certification (AIS Certification).

Delays in the Certification Process due to Chinese New Year Holidays 2019

The Chinese authorities will shut down for several days during the Chinese New Year holidays. According to official announcements, the CCAP (China Certification Centre for Automotive Products) is going to be closed from February 2, 2019 to February 14, 2019. The CQC (China Quality Certification Centre) will also shut down from February 2, 2019 but is set to reopen on February 11, 2019.

The Chinese New Year festivities are the most important holidays of the year in China and lead to record-breaking annual travel activities. With an expected amount of about 400 million travelers, it is the largest annual human migration of people, mainly traveling back to their hometowns to celebrate the holidays with family. Even though New Year’s Eve is officially on February 4, 2019, many companies and authorities close a few days earlier in order to allow their employees to travel during that famously busy period. Commercial activities are expected to resume normally from calendar week 8.

Due to the holidays and business closures, the certification authorities and test laboratories are expected to have delays for CCC applications and ongoing certification processes.

In cooperation with our subsidiaries located in the USA, Europe and China, MPR China Certification GmbH and China Certification Corporation gladly continue to support you with your certification processes during Chinese New Year. Our experience and approach to CCC certification will make the entire process simple and painless.

Information regarding CCC certification, the certification process and their associated costs can be found on our website.

For more detailed information, please download our free booklet “CCC Made Easy” here. You may also consider our book “A Brief Guide to CCC: China Compulsory Certification”, which can be ordered directly on Amazon here .

Please do not hesitate to contact us by phone (UK: +44 2071931135, US: +1 773 654-2673, GER: +49-69-2713769150) or e-mail, us with any questions you may have.

The future of mobility is becoming reality – with self-driving buses in China

Baidu, previously known as the operator of the largest search engine in China, is becoming a technology group and a pioneer in autonomous driving. Self-driving buses were developed with the bus manufacturer King Long United Automotive Industry Co. and recently presented at the Baidu AI Developer Forum in Beijing. The vehicles will be used in a commercial demonstration project at Longlingshan Park in Wuhan, the capital of Hubei Province.

The buses will operate within a radius of 5 kilometers and a speed of 15 km/ h, a safety officer will be available in each bus for a possible emergency. They are equipped with technology for autonomous driving of the so-called Level 4. That means under specified conditions, the buses drive independently and without any intervention by a driver, also there is no steering wheel or cockpit.

Already in July, Baidu had announced that the first 100 self-driving buses were already produced. In addition to the test site in China, in the future the vehicles will be on the road in cities such as Beijing, Xiongan, Shenzhen and Tokyo, said CEO Robin Li Yanhong during the Baidu AI Developer Forum in Beijing. Self-driving vehicles are an integral part of Baidu’s strategy to become a major player in artificial intelligence. This approach is also in line with the announcement by the Chinese government to become the world leader in this area. For this reason, the Beijing-based company Baidu was also given the leading role last year to promote China’s efforts for autonomous driving. If you plan to export products to China for your local market, many products must be CCC certified. We are glad to advise you regarding the China CCC certification.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

E-mobility is gaining importance in India

In recent years, the Indian automotive industry has been able to present numerous innovations and is on the upswing. The industry has the potential to generate over $ 300 billion in revenue by 2026, create 65 million additional jobs, and contribute over 12 percent to India’s GDP. But the population of India is constantly growing and by the year 2031 approximately 600 million people will live in India’s cities. As a result of this consolidation, the subject of intelligent mobility and e-mobility is also gaining in importance, and the Indian automotive industry would like to make an important contribution to this.

As early as 2017, former Indian Energy Minister Piyush Goyal announced that he plans not to sell cars with combustion engines in the country by 2030. While global sales of electric vehicles, with the exception of China, still play a minor role, certain factors and examples from other countries may increase India’s market share of electric vehicles. Many countries promote the production of electric cars and provide incentives for both manufacturers and customers. The technology for electric vehicles is constantly evolving, especially the capacity of the battery and range could be increased. In addition, the necessary infrastructure of the power grid and charging stations must be present in order to be able to charge the vehicles anytime, anywhere. The demand for electric vehicles needs to be boosted. According to McKinsey, the current high price of alternative drive vehicles is one of the main reasons for the reluctance of potential buyers.

The Indian government and automotive industry have recognized this trend and the need for environmentally friendly vehicles. Last year, numerous models were introduced, many of which are developed or produced in India. The portfolio ranges from electric scooters and motorcycles to tricycles to full-blown SUVs. This development will have a significant impact on manufacturers and suppliers in the automotive industry and could lead to change and shifts in the current market.

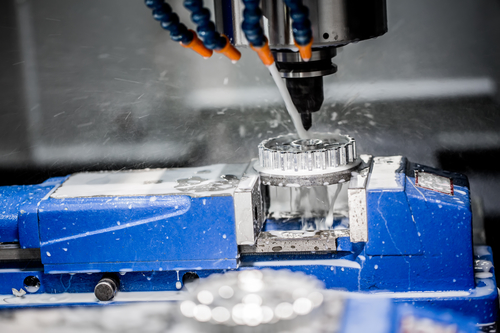

China’s machine production is predicted steady growth for the next four years

According to experts, two markets in particular have particularly good growth opportunities: industrial robots and high-tech production machines with CNC technology. Due to the continued good order situation of the manufacturing industry in China, demand for industrial robots also increased. China is currently the largest sales market for robots and recorded growth of 17 percent per year. Nevertheless, almost half of the industrial robots used in China have to be imported, the countries with the most imports are South Korea, Japan, the USA and Germany. According to the Chinese government’s plan for industrial robot development for the years 2016 to 2020, an expansion of manufacturing capacity from the current 72,400 to 500,000 in 2020 is targeted.

Another sector that predicts solid growth is technologically advanced CNC manufacturing machinery. The majority of Chinese toolmakers have so far only adapted existing technologies or changed them slightly with Western know-how. The majority of high-precision and modern CNC machine tools and accessories must continue to be sourced from abroad. One third of the machines come from Japan and Germany, and less than 20 Chinese companies can currently produce these types of high-end CNC machine tools. In addition to machines for tool production, cutting and forming machines are also in demand.

In China’s move to catch up with rivals such as the US or Germany in the high-tech sector, the government has adopted the “Made in China 2025” strategy, which names 10 key industries, including robotics, aerospace and zero-emission cars. The aim of the strategy is to develop the Chinese machinery industry in such a way that it is in a position to provide the domestic market with its own developments and innovations and to cover the areas of energy, transport, new materials and agricultural machinery. Another priority was the best use of foreign investment capital, management experience and advanced technology. Do you have production sites in China or would you like to export your products? Many consumer and capital goods must be marked with the China Compulsory Certification (CCC) label. We advise you competently in the context of a CCC certification.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly here on Amazon.

Continental builds new plant in India

On December 10, 2018 the groundbreaking ceremony and an opening ceremony for the start of construction of a new Continental plant in Pune, India were held. It’s new factory on the four-hectare site will mainly produce surface materials and artificial leather. The construction costs for the 12,000-square-meter production facility are estimated at around 22 million euros, the capacity should initially be 5 million square meters of materials. As start of series production is planned in 2020 and employs 110 people. In addition to the production facilities, there are also buildings for product development and local purchasing.

Continental’s decision in favor of India to invest in a new plant is, according to Dr. Dirk Leiß, responsible for the Surface Materials Business Unit, that India is now regarded as the fifth largest automobile market in the world. He continued, “Every car has interior materials built in. By investing locally, we can provide our Indian customers with local and customized solutions that are designed and manufactured close to the market.”

Continental has had a sales office in India for six years and supplies the five largest car manufacturers in India as well as one of the largest motorcycle manufacturers from other plants. The new plant ensures fast response times and sustained growth in the Indian market. The factory was designed according to the latest technology and has a biogas plant for energy supply and an environmentally friendly paint shop. Continental chose the Pune site because of its proximity to numerous car manufacturers and suppliers. Continental currently operates eight plants in India and 8,000 employees at a total of 15 locations. In addition, the Continental Technical Center India (TCI) is one of 3 system and technology centers worldwide and employs over 3,000 engineers.

You can also benefit from the growth in India. The export of products to there, especially cars and car parts, requires often a compulsory India Certification according to the Automotive Industry Standard (AIS). We are glad to advise you regarding the AIS certification.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

VW joins Baidu company Apollo

The Baidu subsidiary Apollo and Volkswagen will cooperate more closely in the future in the development of autonomous vehicles. The two companies announced this on 2 November in Beijing. In addition, the Wolfsburg joins the Apollo board and want to strengthen their expertise in China for other brands of the group. For Volkswagen, China is now the largest sales market and has a special significance for new technologies and innovative mobility solutions.

Apollo is part of the Baidu group of companies, whose Internet activites is the Chinese counterpart to Google and with the Apollo project has become one of the world’s leading technology companies for autonomous driving and artificial intelligence. Thanks to the open source approach, more than 130 partners from industry and science have already been able to work together, among them well-known international companies such as Microsoft, Intel, Daimler AG and Ford. With the wide range and expertise of these partners, Apollo can cover most of the relevant areas for self-driving vehicles, which includes, among other things, the sensor technology, other hardware as well as programming and control.

At the launch event of the collaboration, Sven Patuschka, Chief Technical Officer of Volkswagen (China) Investment Co., said Apollo’s open source approach is highly promising and will accelerate the development of autonomous driving. Volkswagen wants to contribute its development expertise of the brands VW and Audi, a first joint project is imminent. Apollo owns a recently build dedicated test site for autonomous driving in Xiongan, China, south of Beijing. There, a Volkswagen test vehicle will be equipped with Apollo software and extensively tested. Vehicles, components and electronic components must pass the China Compulsory Certification (CCC) in China. We advise you on the application and during the approval process of China CCC certification.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly here on Amazon.

Fuel cell as alternative energy source of electric vehicles

In the future, the majority of all vehicles will drive electrically. But should the energy come from batteries that are heavy, or a fuel cell that needs an equally heavy and solid tank for the hydrogen? It is unclear which system can finally prevail or whether there will even be a side by side — similar to the current gasoline and diesel fuel situation.

China has decided — in the current five-year plan, the development of the fuel cell plays an important role. The government declares that it will invest in the necessary infrastructure by the year 2030 and that by then there will be 3,000 hydrogen filling stations. In Japan, Toyota is also focusing on the fuel cell as the engine of the future. Here, the necessary electricity for the production of hydrogen gas is to be delivered from coal power plants. These are equipped with modern CCS technology, which separates and stores the climate-damaging CO2 gas. Europe is changing course, relying on batteries and promoting development and production in the EU. The German government also supports the producers of battery cells with subsidies and tax benefits. Often these are companies from China that are building new production facilities in Germany, as there are already overcapacities for batteries in the Far East country.

Most automotive manufacturers and suppliers do not want to commit to a technology yet. Bosch, for example, does not build batteries itself, but is researching the development of the fuel cell. In the US, the young company Nikola is developing a hydrogen-powered heavy-duty truck together with Bosch. Here, Nikola supplies the fuel cell technology while in the future truck a modular E-axis from Bosch is used, which includes the engine, the electronics and a gearbox. Daimler has with the Mercedes GLC F-Cell already a series production vehicle with a fuel cell in its portfolio and wants to build a network of 400 hydrogen filling stations in Germany with a joint venture H2 Mobility. Renault, since 2010 a cooperation partner of Daimler, however, relies on the battery technology. From 2025, newly developed solid-state batteries are to be used here, which are more powerful and cheaper than the conventional lithium-ion batteries. For example, the fuel cell for trucks and the battery for cars could prevail.

The electric car start-up e.Go Mobile takes a different approach. It wants to use the fuel cell as a range extender. In this case, a battery is charged with a fuel cell, which in turn drives an electric motor. As a result, this system can be used in many vehicles. The joint venture e.Go Rex is to be founded this year together with Proton Motor Fuel Cell for production and development. Starting in 2019, e.Go Mobil will work with ZF Friedrichshafen to produce the e.Go Mover autonomous electric minibus and is also planning an electric compact car called e.Go Life. Do you want to export or produce your products to China? Do you need the China Compulsory Certification (CCC)? We can advise.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

Faurecia establishes new joint venture in China

Faurecia, one of the world’s leading automotive suppliers, has joined Liuzhou Wuling Automotive Industry Co., Ltd. and founded another joint venture, this time in the area of “Clean Mobility”. Previously, the two companies had already established joint ventures for car seats and vehicle interiors and have been working together successfully in these sectors for several years. The new company is called Faurecia (Liuzhou) Emissions Control Technologies Co., Ltd. and the two parties each hold 50 percent of the shares. For the year 2023, a turnover of 600 million CNY (equivalent to 86 million USD) is desired.

The new company will cover all previous business areas of Wuling Industry and integrate the four existing plants in China. With the joint venture, Faurecia and Wuling Industry are hoping for a comprehensive and joint strategic cooperation in the field of automotive exhaust systems. In addition, products are to be developed and produced for a Wuling partner, SAIC GM Wuling Automobile Co., Ltd. and its affiliates.

Announcing the new joint venture in late October this year, Christophe Schmitt, executive vice president of Faurecia Clean Mobility, praised the collaboration with Wuling to date and the new opportunities for even better cooperation with Chinese OEMs in response to an increasing demand in the Chinese market as part of emission-free mobility solutions.

Faurecia’s partner, Wuling Industry, has 60 years experience in the automotive industry. They are involved in the design and production of vehicles as well as a supplier for parts, motors and special vehicles. The company has locations in China in Guangxi, Chongqing, Shandong and Guizhou as well as in Indonesia and India.

You are in the automotive industry and you want to market your products in China or produce them locally? We are glad to advise you in the context of the mandatory CCC certification (China Compulsory Certification (CCC)).

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.