BMW signs long-term contract with Chinese battery supplier CATL

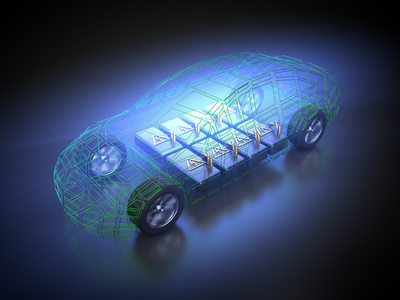

BMW has signed a long-term contract with Chinese battery supplier CATL. The long-term contract for a total of 1.5 billion euros includes the delivery of battery cells from a new CATL factory in Erfurt. Well-known German car manufacturers, including Volkswagen and BMW as well as suppliers Bosch, had long been discussing the economic viability of such a new production facility for lithium-ion batteries. Now the Chinese company CATL (Contemporary Amperex Technology) came before them and plans to build a factory for batteries near Erfurt.

The German automaker BMW announced last week that it had already placed an order for the production of batteries by CATL. The order volume amounts to several billion euros and the production of the batteries was supposed to take place near the BMW plant in the south of Germany.

One of the reasons for the local production of battery cells is the relatively high weight, which makes the transport expensive and the classification as dangerous goods, which makes the just-in-time logistics by air freight impossible. To date, only manufacturers from South Korea have established themselves for the production of battery cells in Europe. LG Chem operates a plant in Poland, Samsung one in Hungary. These plants mainly supply the customers Volkswagen and Audi.

Now CATL announced that it would build its first factory in an industrial area close to a highway near Erfurt. The decision in favor of Erfurt was due to the central location and convenient transport links and the Erfurt-based Fraunhofer Institute. The official presentation of the plans is scheduled for the German-Chinese intergovernmental negotiations next week. It would be the first Chinese investment in battery cell production in Europe.

According to CATL, there is sufficient demand for batteries in the German and European markets. In addition to the supply contract with BMW, Daimler is also showing interest in the products from the future production of CATL. It is also possible that BMW and Daimler could jointly conclude a supply contract on more favorable terms.

Electronic vehicles need to obtain a CCC certificate in order to be sold on the Chinese market.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

German Chamber of Commerce Export Academy Seminar on „China Certification – Spare Parts Management for Mechanical Engineers”

The Export Academy of the German Chamber of Commerce invites you to their seminar: “Certification China – Spare Parts Management for Mechanical Engineers” on November 14th, 2018*. A senior consultant from MPR China Certification GmbH will be present to provide first-hand information about various aspects of the CCC certification. *Update: The event has been postponed and will now take place in 2019. We will inform you here as soon as the new date is available.

For the second year in a row, China is Germany’s most important trading partner. But it is not only the automotive industry that is booming in the Middle Kingdom. German mechanical engineers have also been experiencing rising exports for the past 20 years. In this situation, the spare parts business more and more often poses a challenge to many firms: Spare parts, such as plugs, cables, sensors, lights and relays are being detained by the Chinese customs on a regular basis with a missing CCC certificate being the justification. Sometimes a proof of CEL certification is required as well.

The IHK Export Academy would like to use this chance and provide an exclusive seminar on the subject. Important information will be provided on the topics of CCC and CEL certification, the certification processes and the possibilities of obtaining a CCC Clearance Certificate. On top of that, the limited number of participants will ensure that there is still enough space to discuss your individual questions in detail.

All interested parties are cordially invited to register at the Export Academy of the German Chamber of Commerce until October 30th, 2018. The event will take place on November 14th, 2018 in the premises of the Chamber of Commerce of the region Stuttgart: Jägerstraße 30, 70174 Stuttgart.

For further information please visit the website of the Export Academy of the German Chamber of Commerce (German).

Since 2005, the China Certification Corporation has been helping companies around the world obtain CCC (China Compulsory Certification).

If you would like more Information regarding CCC certification, please visit our website. Here you can learn more about the certification process and the costs associated with certification. You will also find details regarding our certification package on our website including a general anticipated time frame. Take a look at our references section to see some of our clients and what they are saying about us. For more detailed information please download our free booklet “CCC Made Easy” here. You may also consider our book “A Brief Guide to CCC: China Compulsory Certification”, which can be ordered directly on Amazon here.

Daimler and BAIC are expanding the production of their Chinese plants

Daimler and BAIC are expanding the production of their Chinese plants. In addition to the production of vehicles and engines, Daimler and BAIC are also investing in the further development of alternative drives and vehicles in China. For this purpose, a new battery factory will be built on the BBAC factory premises. In addition, the expansion of a second plant in Shunyi, Beijing is planned to increase production capacity.

The world’s largest Mercedes-Benz plant is located in southwest Beijing. With a total of 430,000 produced vehicles, 70 percent of total sales generated in China are produced in this plant. In China, Mercedes-Benz set its seventh consecutive production record in 2017. Almost the entire product range is produced locally, including a long version of the A-Class, which is only produced in China.

Together with its local partner BAIC, Daimler has been manufacturing vehicles since 2006, and since 2013, engines have also been produced there. Due to high demand and good cooperation, local production is now being expanded with a battery plant, a new engine factory and a second, complete plant. The new plant in the Shunyi district is to produce 150,000 vehicles a year from 2020 onwards. It has a car body construction, a pressing plant, a paint shop and the final assembly.

In addition, innovation is a priority at the Chinese production sites. The further development of alternative drives and emission-free vehicles will predominantly occur here. This is how the first model of the new Mercedes-Benz EQ brand, the EQ SUV, is being built at the Beijing plant. The start of production is scheduled for 2019.

They are proud of the quality and process reliability in the Beijing plant. It was awarded the title of “Factory of the Year” in 2017 in the category “Excellent Serial Assembly”. Newly developed analytical methods for process control and quality assurance use data from sensors and machines, which are evaluated in real time. An automated guided vehicle (AGV) system is used for efficient material supply in the final assembly on the belt. It consists of shopping carts and lattice boxes, which are networked with the plant’s IT system and deliver the right components at the right time.

The China CCC certification is also needed for vehicles produced in China as well as imported vehicles.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly here on Amazon.

Volkswagen Group China and SEAT are planning a cooperation with Chinese electromobility joint venture

Volkswagen China JAC automobile (which is the Chinese Volkswagen Joint Venture in the electromobility segment) and SEAT have signed a memorandum of understanding last week. This is a clear evidence that the Spanish Volkswagen company is planning to appear on the Chinese market again.

In order to build electromobility vehicles for the Chinese market, SEAT is planning to become a shareholder of the Chinese Joint-Venture JAC starting as of 2021. It is not clear yet which type of shareholder SEAT and JAC will be choosing. But, in fact, SEAT will appear as a cooperation partner of JAC on the Chinese market, but as a stand-alone brand.

During the last years the Spanish automotive company has tried to get into the Chinese market several times, but without success. Now, Volkswagen hopes that its Spanish subsidiary company will be more successful with own electromobility vehicles.

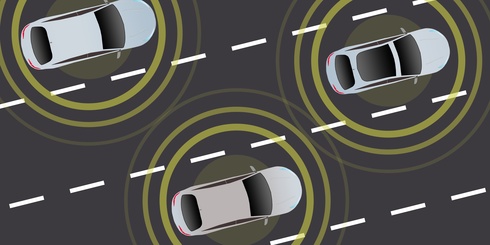

Besides, SEAT, JAC and Volkswagen China are planning to build a new research and development centre until 2021 in order to succeed in the Chinese market with cars developed in China. Their new R&D centres’ purpose is to develop own electromobility vehicles, and to do research specifically in the fields of connectivity and autonomous driving.

Chinese companies, manufacturing in China must also ensure compliance with GB standards through CCC certification.

Information on how CCC certification could affect your business, or information about CCC certification in general, the process, and associated costs, can be found on our website and in our news section. There you will find up-to-date information twice a week.

Please do not hesitate to contact us for further details and advice. You can contact us via e-mail or call us on +49692713769150.

You can also view our free CCC brochure, which you can download here as a PDF file, or you can consult our book “CCC: China Compulsory Certification”, which can be found directly here on Amazon.

New Cooperation Between Chinese and German Car Manufacturers

At the beginning of July 2018 Chinese Prime Minister, Li Keqiang, and the German Chancellor, Angela Merkel, met in Berlin and witnessed the successful cooperation between German and Chinese car manufacturers.

Several major car manufacturers such as BMW, Daimler and VW will rely even more on cooperation with Chinese automotive companies in the future.

At the former Tempelhof Airport various carmakers presented their concepts of autonomous driving.

Autonomous driving is considered to be one of the most important future technologies of the automotive industry. Manufacturers from both China and Germany are showing great interest in working together to stay ahead of the technological race.

The advancement of electric mobility is also an objective of cooperation. China is currently the fastest growing car market worldwide and alternative drive concepts are also on the rise.

In addition to technological synergy effects, the participants also hope to develop common standards.

Prime Minister Li Keqiang reiterated that China is very open to German industry, with production in China itself also benefiting from the cooperation.

The BMW Group and the Chinese manufacturer Great Wall came to an agreement to produce the Mini E in China in the future.

Chinese companies, manufacturing in China must also ensure compliance with GB standards through CCC certification.

Information on how CCC certification could affect your business, or information about CCC certification in general, the process, and associated costs, can be found on our website and in our news section. There you will find up-to-date information twice a week.

Please do not hesitate to contact us for further details and advice. You can contact us via e-mail or call us on +49692713769150.

You can also view our free CCC brochure, which you can download here as a PDF file, or you can consult our book “CCC: China Compulsory Certification”, which can be found directly here on Amazon.

French supplier Faurecia signs strategic collaboration with Chinese automaker FAW Group

France-based automotive supplier Faurecia and one of the leading Chinese automakers, the FAW Group, signed a strategic cooperation agreement on 11 June 2018. Faurecia’s goal in this step is to expand its presence in the Chinese market and intensify its collaboration with local Chinese automakers and suppliers. The core of the collaboration will be the development of a so-called “cockpit of the future” as well as clean and sustainable mobility solutions. Faurecia is one of the world leaders in both areas.

The concept of the cockpit of the future was unveiled at the beginning of 2018 at CES in Las Vegas and features a driver-specific dashboard, novel speaker systems, more comfortable seats, personalized vehicle settings and an app that helps the driver save fuel and indicates the shortest way to free parking spots. In the area of sustainable mobility solutions, Faurecia has created a new business area. Since acquiring EMCON Technologies in February 2010, Faurecia has been the global market leader in exhaust systems and emissions control.

The FAW Group expects the cooperation to improve the quality of its luxury brand Hongqi (red flag). In particular, benefit from Faurecia’s expertise to redesign and enhance the interior design and seats. FAW is one of the big four Chinese automakers and produced 3 million vehicles in the past year 2017. Beside SAIC, the FAW Group is one of the joint venture companies of Volkswagen and Audi. In addition, FAW has numerous other cooperation’s with, among others, Toyota, Daihatsu and General Motors.

Interior products such as cockpits need a CCC certification for the Chinese market.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly here on Amazon.

Chinese start-up company Byton introduces electric car – targeted launch next year

Only a few months after the release of a prototype and a design study, Chinese electric car startup Byton last week unveiled its new K-Byte model to the public. The sedan was presented in the run-up to the CES Asia show, the SUV and crossover M-Byte already celebrated its premiere at the CES in Las Vegas in January. The basic version of the first model has a 71-kilowatt motor, sufficient battery power for 400 km, and will cost approximately $ 45,000.

The new K-Byte will be equipped with level 4 driver assistance systems, which means largely autonomous driving. The vehicle can move alone on the road to a great extent, the driver only has to intervene in certain situations. The autonomous driving technology comes from Aurora Innovation, which was founded by the former CEO of Google’s self-driving car division, Waymo. Currently only self-driving level 2 cars are allowed in the US. Also, the vehicles of Tesla are in this category. However, they will soon have completed the development to level 3 and 4, assured Tesla chairman Elon Musk.

The young company Byton has ambitious plans. The SUV and crossover M-Byte should have its market introduction at the end of the year 2019, the K-Byte follows in 2021. A third vehicle as a minivan is already in planning. As part of the K-Byte premiere, Byton also announced that it had raised $ 500 million in funds. The money comes mainly from the Chinese automaker FAW and the battery manufacturer Contemporary Amperex Technology (CATL). FAW is involved in a joint venture with Volkswagen, while CATL is the world’s leading manufacturer of batteries for electric cars. Byton recently opened its corporate headquarters in Nanjing and already owns a research and development center in Silicon Valley, USA and a design center in Germany.

Electric vehicles as well as vehicles with combustion engine need a CCC certification in order to be sold on the Chinese market.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly here on Amazon.

Chinese automotive supplier Ningbo Jinfeng Auto Parts plans acquisition of German competitor Grammer AG

The management of Grammer AG reacted positively to the offer and supported the takeover project. Ningo Jifeng Auto Parts already holds 25 percent of Grammer’s shares following an increase in October 2017. The contract includes a job guarantee over 7.5 years for the employees of Grammer.

The offer from the Chinese comes just at the right time for the German automotive supplier in an attempt to further reduce the equity share of the Bosnian investor Hastor / Prevent Group.

In the past, the supplier Prevent Group, known as a “rebel”, had some difficulties with its business partners, including Volkswagen. This also affected Grammer AG when placing orders. Now, they hope to profit from the takeover twice, from new orders in Germany as well as from Ningbo Jinfeng in China.

Ningbo Jinfeng Auto Parts is an automotive supplier in China specializing in the development and production of automotive seat components, including headrests and armrests. The company was founded in 1996 and is headquartered in Ningbo south of Shanghai. More than 2,600 employees work at 8 locations in China. Sales in 2015 amounted to 155 million euros. They already own a company in Europe, the Jinfeng Interior Automotive with production sites in the Czech Republic and Bosnia-Herzegovina.

Grammer AG is headquartered in Amberg, southeastern Germany. The corporation specializes in the development and manufacture of components and systems for the interior decoration of cars, as well as seats for commercial vehicles, buses and trains. Two new plants were opened in China as early as 2005, followed by expansion into the Russian truck market in 2008 and the expansion of the center console business in Asia and the North American free trade zone NAFTA in 2010. Shortly before the purchase offer from Ningbo, Grammer acquired the American Toledo Molding & Die Inc. (TMD) for approximately $ 271 million.

The management and the executive board of Grammer have already waved the takeover by Ningbo Jinfeng, the approval of the German authorities is considered safe.

Many parts produced by Grammer and Ningbo Jinfeng need a CCC certification for the Chinese market.

For more information on how CCC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our news section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly here on Amazon.

Participation in the CCAP International Forum for Technology and Quality of Automobiles and Components in Chengdu

On June 28, 2018 China Certification Center for Automotive Products (CCAP) held the CCAP International Forum on Technology and Quality of Automotive and Components on their twentieth anniversary in Chengdu. Over 300 industry representatives from all over the world were invited. The purpose of the event was to inform the attendees of the latest trends in quality and registration of vehicles and the automotive components in China.

MPR China Certification GmbH was represented at the forum by managing director Julian Busch. The opening speeches were made by representatives from the CNCA, CNAS, CAM and CCAA. Afterwards the head of the CCAP Mr. Fu Zhijian presented the goals and principles of the CCAP and presented the future plans of CCAP.

Representatives from German companies and the VDA QMC China presented important principles of a modern quality management system, in addition to numerous high-profile speakers from Chinese institutions and companies.

The CEO of the Taiwanese VSCC, which is responsible for the Taiwan Certification, also presented his agency’s certification system and the special features of the Taiwanese market. Many speeches highlighted the importance of ongoing quality control, which also plays a main role in CCC certification. The conference concluded with a banquet in which all participants exchanged their experiences of the day.